Call Us:- 08045801637

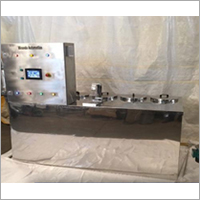

Powder Handling and Dosing System

Product Details:

- Product Type Powder Handling and Dosing System

- Material Stainless Steel

- Automatic Yes

- Drive Type Electric

- Color Sliver

- Click to view more

X

Powder Handling and Dosing System Price And Quantity

- INR/Piece

- 1 Piece

Powder Handling and Dosing System Product Specifications

- Powder Handling and Dosing System

- Yes

- Sliver

- Stainless Steel

- Electric

Powder Handling and Dosing System Trade Information

- 10 Piece Per Month

- 2 Months

- All India

- ISO 9001:2008.

Product Description

We are known as a recognized entity in the market, engaged in manufacturing and exporting Powder Handling and Dosing System. It is manufactured at our advanced production unit under the guidance of our experts by using high quality materials as per industry laid quality standards. For handling powders, this machine is widely used in the food processing, pharmaceutical and chemical industry. Durable stainless steel powder handling and dosing machine is available for our clients at an affordable price.

Features of Powder Handling and Dosing System:

1. Minimum maintenance

2. Low energy consumption

3. Rugged construction

Advantages of Powder Handling and Dosing System:

1. Less flour spillage

2. Dust free environment

3. System hygienic and easy to clean

Applications of Powder Handling and Dosing System:

1. Food processing industry

2. Bakery industry

3. Chemical industry

4. Pharmaceutical industry

Powder Handling and Dosing System Working Process:

1. Directly from bags or silo, flour is drawn by using aerial bag tilter.

2. First flours goes through magnetic grill and after via gyro monitor siever into an aerial pressure pump, which is affixed on load cell.

3. From pneumatic pump, the flour is conveyed intactly by using dense stage transferal advancement, into silos fixed on head of mixers.

4. Flour dosing system and handling system helps multiple blenders functioning in various recipes.

5. Precise dosing information is well-kept product wise, mixer wise and batch wise.

6. Right from the flour receipt in tankers or bags, the Flour handling system performs the tasks of flour screening, metal detection and storing flour in silos through the activity of pneumatic transfer. Even flour blending can be provisioned along with the transfer system and pneumatic weighting.

Enter Buying Requirement Details

Other Products in 'Dosing System' category

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese